Dedicated to Innovation. Committed to Our Clients’ Success.

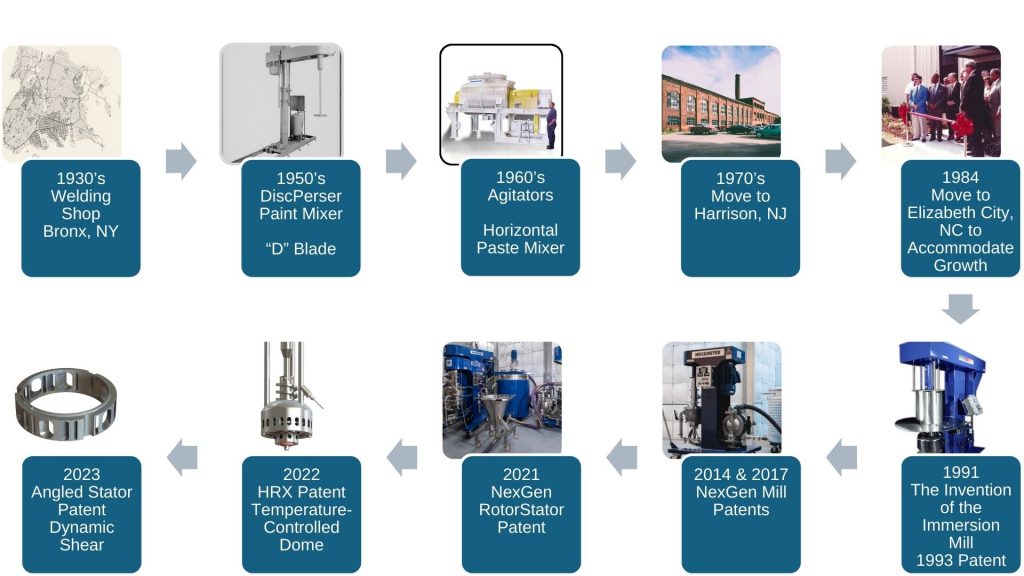

Hockmeyer began as a welding and repair shop in The Bronx, New York, in the mid-1930s, and continues to evolve to fit the needs of our customers and various businesses within the mixing industry. DiscPerser, Hockmeyer’s original innovative machine, was introduced in the early 1950s along with a unique ring style “D” blade that revolutionized the way paint and ink were manufactured.

During the 1960s and 1970s, new machines were added to the Hockmeyer line including horizontal paste mixers, multi-shave mixers, pony mixers, paddle blade agitators, paper balers, and attritors. Due to demand and growth, the Hockmeyer factory was moved to a larger space in Harrison, NJ, and then relocated again in 1984 to an even larger facility in Elizabeth City, North Carolina, where we continue to expand and innovate to this day.

Hockmeyer has always prided itself in growing with our customers, and in the 1990s, HEC made another quantum leap in dispersion technology with the introduction of the Hockmeyer Immersion Mill, the first-ever in the industry. This development came in two parts, both of which were extremely impactful, each time boosting efficiency by minimizing waste and considerably shortening the process times for many applications. Nanometer milling capabilities were then added as an ability to grind particles into the <100 nm range, which expanded the reach of Hockmeyer equipment into new industries and new applications. The next major development was the NEXGEN™ Mill, bringing the immersion milling technology to a new level: adding vacuum, rapid recirculation, and more temperature regulation, all of which are key contributors in the milling process, introducing portability and a smaller footprint for tight spaces at the same time.

Today, Hockmeyer continues to lead the industry with unmatched performance of this latest and continuously evolving technology and customer service. When choosing equipment for your company, Hockmeyer will assist you in evaluating process time, product loss, ergonomics, scale-up, cleanability, and the ability to meet standards. At Hockmeyer’s testing facility, laboratory models are available, as well as pilot size and production equipment to help develop processes and choose the right machine for your business. And initial testing is always free.