-

Maintenance Cart

Features & Benefits Specifically designed for easy disassembly of the Immersion Mill during cleaning, media, screen, or peg changes. Compatible with all models, offering interchangeability. Mounted on casters for effortless…

View Maintenance Cart

-

Jacketed Tanks

Features & Benefits Ideal for high-temperature industrial processing applications. They excel in temperature transfer for thermal fluid operations. Can be divided into multi-pass zones, enhancing process flexibility.

View Jacketed Tanks

-

Manufacturing Tanks

Features & Benefits Offer manufacturing tanks in both portable and stationary options. Varied shell thicknesses available to optimize heating and cooling management. Available in baffled and unbaffled styles. Options include…

View Manufacturing Tanks

-

Dimple Jacketed Tanks

Features & Benefits Utilizes natural turbulence through dimpled points for efficient thermal fluid system. Features a light-gauge metal jacket attached to the original vessel. Offers advantageous strength and durability without…

View Dimple Jacketed Tanks

-

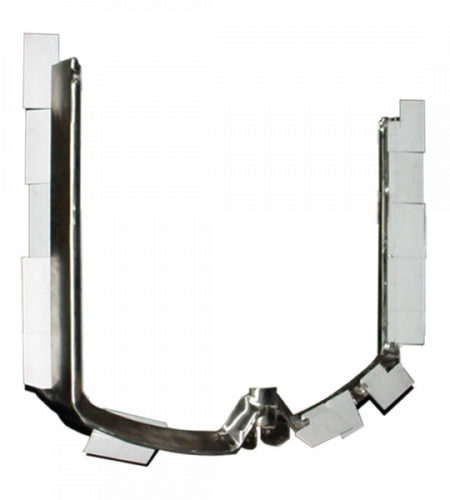

Single-Arm Helical Blade

Machine Features Lower horsepower consumption Superior batch turnover Better heat transfer Easy batch clean-up Single-Arm Helical Blade Benefits This blade allows for efficiently directed scraper flow off the wall of…

View Single-Arm Helical Blade

-

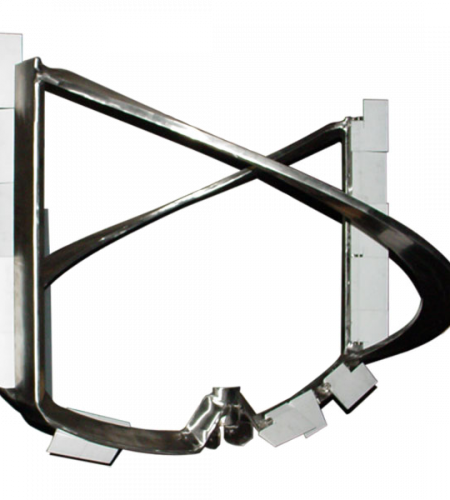

Anchor Sweep Blade

Machine Features Move product off vessel wall Improves heat transfer Eliminates batch dead zones TRIANGULAR RISER STRUCTURE WITH TEFLON SCRAPERS FOR SWEEP BLADES This is Hockmeyer’s premium design. This type…

View Anchor Sweep Blade

-

Helical Sweep Blade

Machine Features Move product off vessel wall Moves mixture to the middle of the tank Move high-viscosity material towards the high-speed blade Operates in clockwise and counterclockwise directions Riser Blade…

View Helical Sweep Blade

-

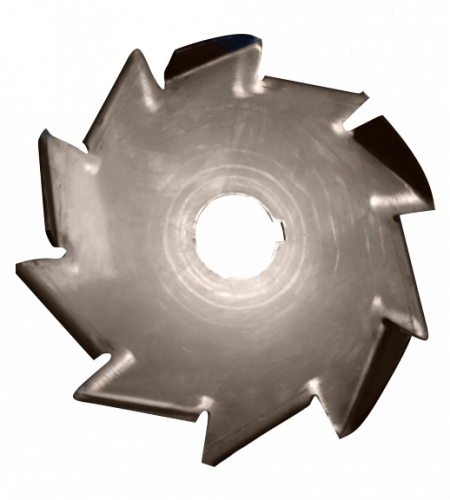

G – Blade

Machine Features Designed for maximum turbulent flow Utilize for high-speed blending and agitation Effective for heavy-bodied and thixotropic systems

View G – Blade

-

D – Blade

Machine Features Optimizes disperser performance Double cutting of inner and outer blades The ‘D’ Blade creates velocity differentials and a high-pressure zone within the rings. As the product is discharged…

View D – Blade

-

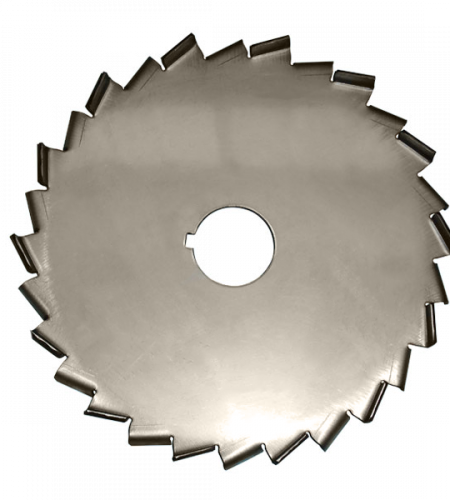

F – Blade

Machine Features Constructed of durable 304 stainless steel Teeth control turbulent and laminar flow Teeth have uniform size and height The ‘F’ style saw tooth blade is one of the…

View F – Blade

-

E – Blade

Machine Features Used for high viscosities and loading solids Teeth vary in height and are set at different angles

View E – Blade

-

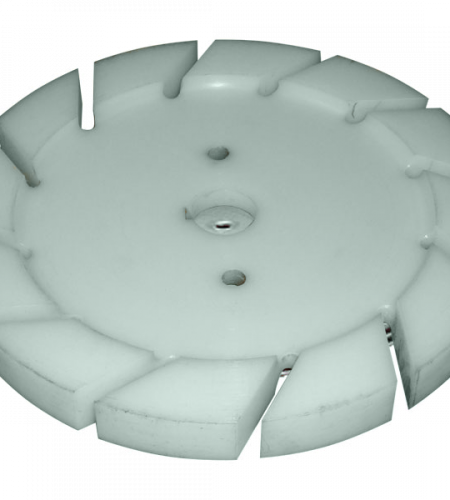

Poly Blade

Machine Features Works more service Better pumping capacity More shear Better dispersion times Production Benefits Customers are reporting certain dispersion times can be reduced by as much as 60%. One…

View Poly Blade

-

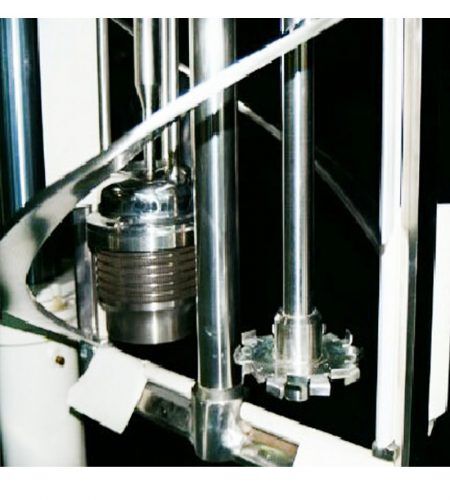

Multi-Tasking System

STREAMLINE YOUR PROCESS: SAME TANK, SAME PLACE, FROM START TO FINISH We offer this unit with a variety of mixing tools to suit our customer’s unique needs. Whether you need…

View Multi-Tasking System

About Us

Hockmeyer Equipment Corporation has been providing process solutions for over 80 years. We are a leader in the Wet Grinding and Dispersion Industry and offer custom designed processing equipment for mixing, blending, dispersing, and particle size reduction. The Hockmeyer team is dedicated to designing processing equipment that is of the highest quality available. Our goal is to increase the profitablity of our customers through continuous innovations in process innovations in process technology.

Services

-

Customer Testing-Applications Lab

Don’t trust promises, trust results! Hockmeyer offers it’s Customer Service Laboratory to show you exactly how our equipment will increase your product quality and efficiency!

-

Test-To-Own Demo Program

Hockmeyer machines are guaranteed to enhance your process. Before purchasing equipment, schedule an appointment with our Lab Technicians and see how machines meet your process needs.