Features & Specifications

Machine Features

- Optimizes disperser performance

- Double cutting of inner and outer blades

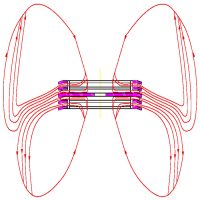

The ‘D’ Blade creates velocity differentials and a high-pressure zone within the rings. As the product is discharged into the low-pressure area outside the rings, a venturi effect is created, splitting and tearing the fluid as it is discharged. Additional heat is created as a by-product of the higher shear. However, the higher shear level eliminates or dramatically reduces any subsequent milling that may have previously been required.

The “Ring” blade is a patented Hockmeyer innovation. The secret of this blade? The double-cutting combination of the teeth and outer blades, or rings. These allow the blade to disperse, deagglomerate, dissolve, and emulsify. The “Ring” blade handles the toughest pigment agglomerates and rapidly dissolves resins, gums, and similar materials. It even works effectively within a liquid/liquid system, creating a film-splitting venturi effect.

Product Documents

Image Gallery

Services

-

Stock Machines & Tanks NEW & USED

Our dedication to customer satisfaction doesn’t stop with the purchase.

-

Field Training & Support

Hockmeyer is dedicated to providing best-in-class support to maintain the lifespan and efficiency of your Hockmeyer equipment.

-

Equipment Support Program

Learn about how Hockmeyer can provide dedicated service, maintenance, and training through our Equipment Support Program.