Features & Specifications

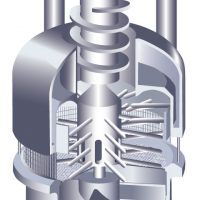

Machine Features

- 20 Hp

- 115″ Overall Height, 36″ Stroke, 22″ Width

- Water-cooled dome for temperature control

- Upper auger to consistently feed material into the mill chamber

- Variable Frequency Inverter

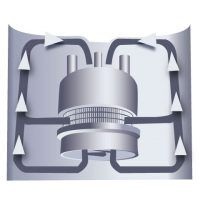

- A compact wall-mounted column uses a counter-balance for manually raising and lowering the machine

- 8” Diameter Basket – 2.5 Liter Media Capacity. Basket available with .27 mm and .5 mm slots

- 1-Liter Media Basket also available

- Turbo or Marine Style Propeller

- Start and Stop Push Buttons, a Speed Potentiometer, Jog and Emergency Stop

- Safety Features include a Height Limit Switch, Shaft Guard and Can Lock

- Support Legs available for Floor Mounting

Covered by one or more of the following patents: 5,184,783; 5,497,948; 5,820,040; 7,175,118; 7,559.493; 7,828,234; 7,883,036; 7,914,200; 8,182,133; 8,376,252; 8,733,677; 9,597,691 B1

Product Documents

Image Gallery

Services

-

Stock Machines & Tanks NEW & USED

Our dedication to customer satisfaction doesn’t stop with the purchase.

-

Field Training & Support

Hockmeyer is dedicated to providing best-in-class support to maintain the lifespan and efficiency of your Hockmeyer equipment.

-

Equipment Support Program

Learn about how Hockmeyer can provide dedicated service, maintenance, and training through our Equipment Support Program.