Features & Specifications

Machine Features

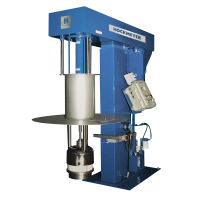

- Multiple tank positions with 360º rotation available

- Minimal cross-contamination, easy clean-up, and low solvent loss

- Maximizes color development, strength, gloss, durability, and yield

- Reduction of process time versus traditional milling techniques

- Highly efficient using small quantities of media

- Use media as small as .5 mm and as large as 2 mm

- Consistent performance

- Various materials of construction available

- Tight Particle Distribution

- Fast processing times

- High product recovery – reduced raw material loss

Covered by one or more of the following patents: 5,184,783; 5,497,948; 5,820,040; 7,175,118; 7,559.493; 7,828,234; 7,883,036; 7,914,200; 8,182,133; 8,376,252; 8,733,677; 9,597,691 B1

The HCP Immersion Mill: A History of Milling Excellence

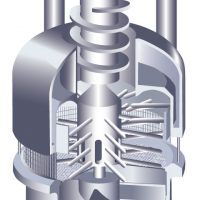

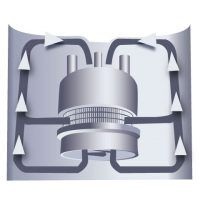

The immersion mill was invented and patented by Hockmeyer in the 1990s to replace the outmoded horizontal milling technologies and three roll mills that process the feedstock very slowly through the shear zone, are cumbersome to disassemble and clean, are labor-intensive, and are relatively inefficient by modern-day standards.

In immersion milling, the feedstock is circulated through a powerful and turbulent shear zone at a very high velocity, as fast as 50 passes per hour. This produces very narrow particle size distributions, decreases the bead-to-product ratio necessary for efficient milling, and dramatically increases productivity and throughput. Over the years, Hockmeyer has continued to improve on the original design by adding more impact points, flow boosters, high-viscosity models (HCPS), and nano-milling features.

| Model | RECOMMENDED Batch Size Min/Max (Gallons)

Larger batch sizes will require longer milling times |

Media Volume (Liters) |

|---|---|---|

| Micromill | 250 ml / 2 liter | 49 ML |

| HCP - ¼ | 1 / 5 | 0.25 |

| HCP - 1 | 5 / 20 | 1 |

| HCP DM 1 | 3 / 15 | 1 |

| HCP DM 2.5 | 20 / 60 | 2.5 |

| HCP - 2.5 | 13 / 35 | 2.5 |

| HCP - 5 | 35 / 60 | 4.5 |

| HCP - 10 | 50 / 150 | 8 |

| HCP - 20 | 120 / 250 | 18 |

| HCP - 40 | 250 / 600 | 35 |

| HCP - 60 | 600 / 800 | 46 |

| HCP - 80 | 800 / 1100 | 63 |

Product Documents

Video & 3D gallery

-

Hockmeyer HCP Quarter Mill

Image Gallery

Services

-

Stock Machines & Tanks NEW & USED

Our dedication to customer satisfaction doesn’t stop with the purchase.

-

Field Training & Support

Hockmeyer is dedicated to providing best-in-class support to maintain the lifespan and efficiency of your Hockmeyer equipment.

-

Equipment Support Program

Learn about how Hockmeyer can provide dedicated service, maintenance, and training through our Equipment Support Program.