Features & Specifications

Machine Features

- Move product off vessel wall

- Moves mixture to the middle of the tank

- Move high-viscosity material towards the high-speed blade

- Operates in clockwise and counterclockwise directions

Riser Blade Benefits

These risers allow the helical blade to move high viscosity material in the batch toward the high-speed blade. The helical sweep blade allows the operator to choose between a clockwise direction (pushing the material up) and a counterclockwise direction (pushing the material down).

These options have a dramatic effect on the batch when the helical blade is pushing downward a long slot is formed on the leeward side of the helical riser allowing powders to fall in. This is very helpful when adding powders to a batch of high viscosity material. Once powders have fallen into the slot behind the helical riser, the second helical riser pushes the material even farther down into the batch. When this powder reaches the bottom of the tank it is forced towards the middle of the tank and into the path of the high-speed disperser. On the other hand, when the helical blade is rotating in a clockwise direction it brings material up from the bottom of the tank and forces it to the top of the batch. This upward movement is especially useful when pulling vacuum on a batch to remove entrapped air.

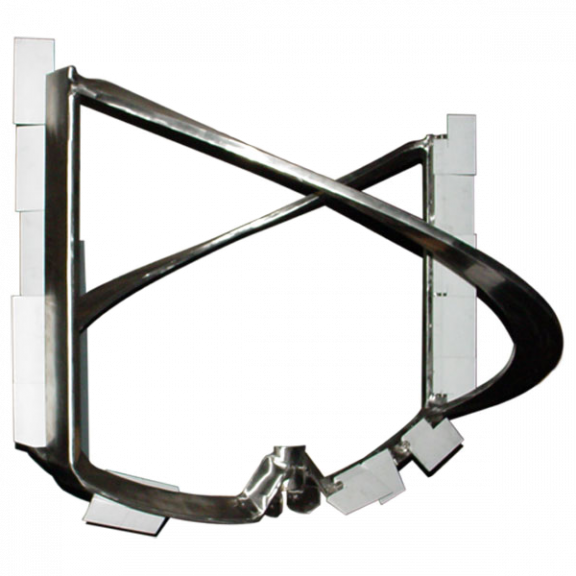

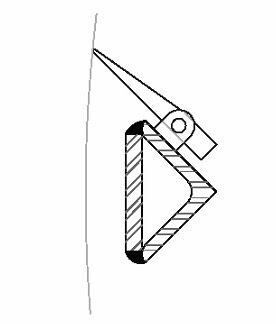

TRIANGULAR RISER STRUCTURE WITH TEFLON SCRAPERS FOR SWEEP BLADES

This is Hockmeyer’s premium design. This type of riser is the strongest and most durable, designed specifically for the type of forces the sweep blade encounters. Also, the three flat sides ease clean-up on high viscosity products. While this is the most expensive option, many customers prefer the longevity and reduced maintenance of this design. No stabilizing rings are required due to the strength of this design.

Services

-

Stock Machines & Tanks NEW & USED

Our dedication to customer satisfaction doesn’t stop with the purchase.

-

Field Training & Support

Hockmeyer is dedicated to providing best-in-class support to maintain the lifespan and efficiency of your Hockmeyer equipment.

-

Equipment Support Program

Learn about how Hockmeyer can provide dedicated service, maintenance, and training through our Equipment Support Program.