Features & Specifications

Features/Options Available

- Sizes from laboratory units to 3500 gallons

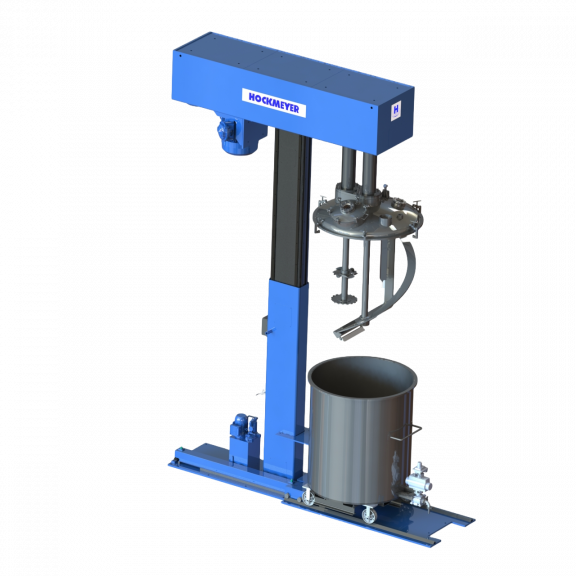

- Hoist or tank mounted configuration

- Inverter driven motors

- Stainless steel or carbon steel material of construction

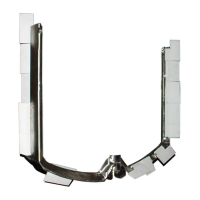

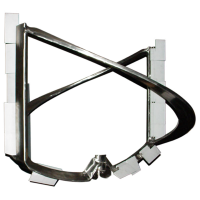

- Helical or anchor sweep low-speed blade, with various high-speed blades available

- Vacuum, pressure, or atmospheric operation

- Electrical components for hazardous environments

- Built-Up Inverter

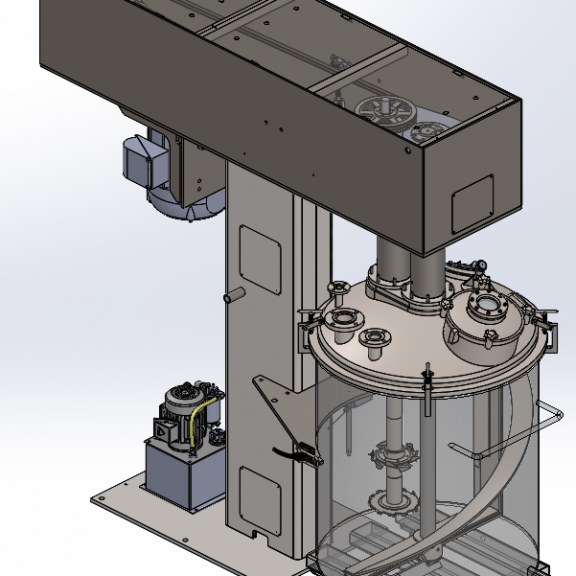

Dual Shaft Mixers

Dual-shaft mixers blend and fold the mass in the vessel and improve product uniformity by scraping the walls. Multi-shaft mixers are most often used to mix medium to high-viscosity products.

A high-speed disperser alone has a limited zone of influence in viscous products, so the low-speed blade is necessary to achieve a homogeneous mixture. When equipped with scrapers, the low-speed blade also aids in heat transfer.

Applications

- Used in the making of printing inks, sealants, caulks, hot melt adhesives, magnetic media slurry, creams, lotions, toothpastes, etc.

The dual-shaft configuration will handle most Multi-shaft mixing jobs. Because it has separate mixing shafts, maintenance is easier on a Dual Shaft than on a Concentric Shaft mixer.

The HOCKMEYER Difference.

Our multi-shaft mixers are designed by an experienced engineering staff incorporating information from customers, our own R&D Laboratory, and data from decades of HOCKMEYER Multi-shaft mixers in service.

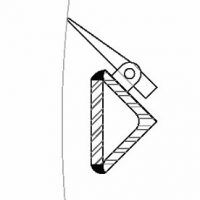

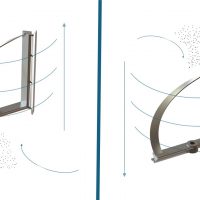

Our standard low-speed blades, for example, use a triangular cross-section, which is both strong and presents a wide profile for efficient mixing action. This design is stronger than a blade made from flat bar and easier to clean than a blade with circular structural elements. Our low-speed blades move product efficiently at relatively low peripheral speeds and typically require less horsepower than our competition’s mixers. Lower tip speeds mean longer life for scrapers.

HOCKMEYER machines have a reputation for performance and reliability. That is by design.

| Model | H.S. HP/L.S. HP | H.S. Blade Dia. | H.S. Tip Speed FPM / L.S. Tip Speed FPM | Holding Gal./Working Gal. | Tank Diameter/Height (inches) |

|---|---|---|---|---|---|

| HHL-II-LAB | 2/1.5 | 2 | 4500/267 | 2/1 | 9.25 x 17 |

| HHL-II-10 | 5/2 | 4 | 4500/237 | 13/10 | 16 x 15 |

| HHL-II-50 | 15/7.5 | 6 | 4500/242 | 60/50 | 26 x 26 |

| HHL-II-100 | 25/10 | 8 | 4500/238 | 159/100-130 | 36 x 36 |

| HHL-II-150 | 30/15 | 10 | 4500/275 | 215/130-180 | 42 x 36 |

| HHL-II-250 | 40/15 | 10 | 4500/215 | 288/200-250 | 42 x 48 |

| HHL-II-300 | 60/20 | 12 | 4500/244 | 376/250-300 | 48 x 48 |

| HHL-II-500 | 60/20 | 14 | 4500/237 | 595/400-500 | 54 x 60 |

| HHL-II-600 | 60/20 | 14 | 4500/262 | 734/500-600 | 60 x 60 |

| HHL-II-800 | 75/25 | 16 | 4500/233 | 990/650-800 | 66 x 62 |

| HHL-II-1000 | 75/25 | 18 | 4500/253 | 1190/850-1000 | 72 x 62 |

Product Documents

Image Gallery

Services

-

Stock Machines & Tanks NEW & USED

Our dedication to customer satisfaction doesn’t stop with the purchase.

-

Field Training & Support

Hockmeyer is dedicated to providing best-in-class support to maintain the lifespan and efficiency of your Hockmeyer equipment.

-

Equipment Support Program

Learn about how Hockmeyer can provide dedicated service, maintenance, and training through our Equipment Support Program.