Features & Specifications

An Ingenious Innovation in Temperature-Regulated Milling suitable for a wide range of viscosities

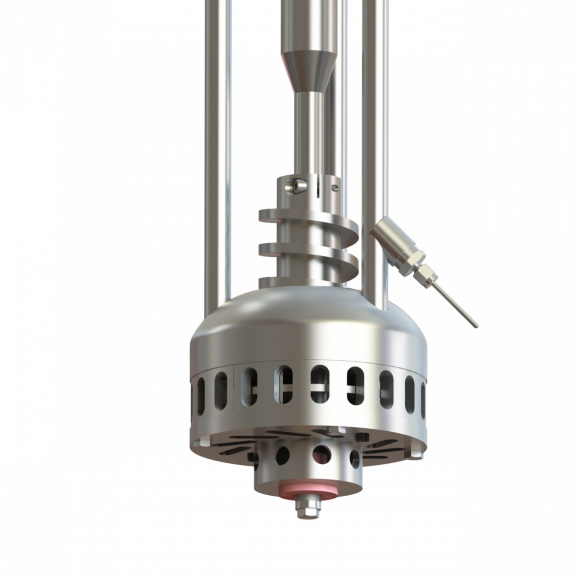

Its ingenious design generates mechanical shear by channeling materials into the rotor, expelling them radially through meticulously sized openings in the stator. With the HRX, a new dimension emerges, catering to products requiring a temperature-regulated environment during processing. Customized stators enable seamless adaptation to virtually any material, accommodating a broad spectrum of incoming particle sizes and viscosities. Welcome to the future of precision milling with the HRX Series.

Precision Shear Control: Variable Speed Functionality Unleashed

Explore the pinnacle of precision control with the HRX Series Temperature-Regulated Immersion Rotor-Stator. Designed for maximum efficiency, this innovative system empowers operators with variable speed functionality, providing precise control over shear intensity. The key to its exceptional performance lies in the intricacies of its design; the clearance between the rotor’s tips and the stator’s interior diameter meticulously governs discharge and shear rates. Tighter tolerances and strategically positioned exit ports amplify shear forces while moderating discharge rates, providing unparalleled versatility.

Optimized Efficiency: Rotor-Stator Clearance Governs Rates

Elevating its capabilities further, the HRX features a jacketed dome, introducing an additional control layer ideal for temperature-sensitive applications. Harnessing the synergy of a high-efficiency rotor and dynamic stator designs, this system achieves rapid deagglomeration and particle reduction with unparalleled finesse. Each stator boasts openings of various sizes, shapes, and angles, ensuring optimal performance across diverse materials.

Shear Mastery: Tight Tolerances, Enhanced Performance

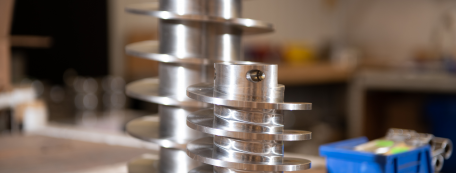

Customizability reaches new heights as operators command exit ports’ positioning, size, and discharge angle, maximizing the machine’s efficacy for specific applications. But the innovation doesn’t stop there. By integrating an auger and sweep blade, the HRX transcends limitations, effortlessly processing materials across unlimited viscosity ranges. Experience precision, versatility, and efficiency redefined with the HRX Series by Hockmeyer Equipment Corp.

Patent Number: 11,766,648

Product Documents

Image Gallery

Services

-

Field Training & Support

Hockmeyer is dedicated to providing best-in-class support to maintain the lifespan and efficiency of your Hockmeyer equipment.

-

Equipment Support Program

Learn about how Hockmeyer can provide dedicated service, maintenance, and training through our Equipment Support Program.

-

Parts & Service

Keep your Hockmeyer equipment running smoothly through our fully-stocked parts department. We offer quick turnaround times that minimize your machine’s downtime.