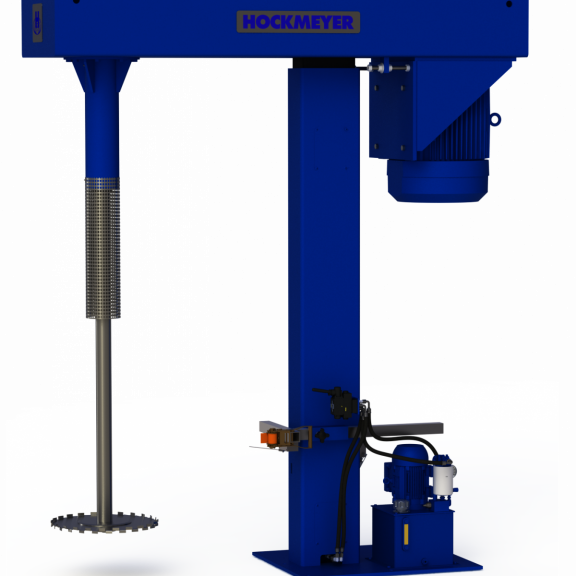

Features & Specifications

Machine Features

- Dissolves; deagglomerates; disperses; emulsifies

- Maximum utility through frequency inverter speed ranges

- Efficient transmission of horsepower

- High-pressure hoist mounted

- Robust; durable design and construction

- Heavy-duty bearings

- Machined bearing seats

- Standard viscosity ranges 1000-50000 CPS for manufacturing flexibility

- Used with portable vessels for convenience and efficiency

- Variable speed, single shaft mixer to disperse, dissolve, deagglomerate & emulsify solid particles in a liquid

- Exclusive Hockmeyer high-pressure hoist mounted lift with zero – 0- packing maintenance when compared to low-pressure lifts

- Environmentally friendly: leak-free performance – no oil leaks, no oil mist, no oil seepage, and 85% less oil usage over standard low-pressure lifts

- No air required – no waiting for air to charge = gained efficiency

| Model | HP | Tip Speed | Rise | Blade Size | Blade Type | Weight (lbs) |

|---|---|---|---|---|---|---|

| HVI - 5 | 5 | 5200 | 36 | 6” | F | 700 |

| HVI - 10 | 10 | 5200 | 54 | 8” | F | 1320 |

| HVI - 15 | 15 | 5200 | 54 | 10” | F | 1500 |

| HVI - 20 | 20 | 5200 | 54 | 12” | F | 1325 |

| HVI - 25 | 25 | 5200 | 54 | 12” | F | 1500 |

| HVI - 30 | 30 | 5200 | 54 | 14” | F | 1900 |

| HVI - 40 | 40 | 5200 | 54 | 14” | F | 2500 |

| HVI - 50 | 50 | 5200 | 54 | 16” | F | 2700 |

| HVI - 60 | 60 | 5200 | 54 | 18” | F | 3000 |

Product Documents

Image Gallery

Services

-

Stock Machines & Tanks NEW & USED

Our dedication to customer satisfaction doesn’t stop with the purchase.

-

Field Training & Support

Hockmeyer is dedicated to providing best-in-class support to maintain the lifespan and efficiency of your Hockmeyer equipment.

-

Equipment Support Program

Learn about how Hockmeyer can provide dedicated service, maintenance, and training through our Equipment Support Program.