Features & Specifications

Machine Features

- Lower horsepower consumption

- Superior batch turnover

- Better heat transfer

- Easy batch clean-up

Single-Arm Helical Blade Benefits

This blade allows for efficiently directed scraper flow off the wall of the vessel and into the path of the leading helix as it travels back to the scraped area. The gradual pitch combined with the broad face of the helix itself results in uniform top-to-bottom turnover while simultaneously improving heat transfer due to the increased dwell time of the feedstock against the wall of the tank. Additional benefits to this design include reduced horsepower requirements and dramatically reduced clean-up time.

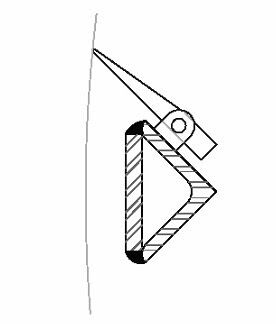

TRIANGULAR RISER STRUCTURE WITH TEFLON SCRAPERS FOR SWEEP BLADES

This is Hockmeyer’s premium design. This type of riser is the strongest and most durable, designed specifically for the kind of forces the sweep blade encounters. Also, the three flat sides ease clean-up on high-viscosity products. While this is the most expensive option, many customers prefer the longevity and reduced maintenance of this design. No stabilizing rings are required due to the strength of this design.

Services

-

Stock Machines & Tanks NEW & USED

Our dedication to customer satisfaction doesn’t stop with the purchase.

-

Field Training & Support

Hockmeyer is dedicated to providing best-in-class support to maintain the lifespan and efficiency of your Hockmeyer equipment.

-

Equipment Support Program

Learn about how Hockmeyer can provide dedicated service, maintenance, and training through our Equipment Support Program.