Features & Specifications

Machine Features

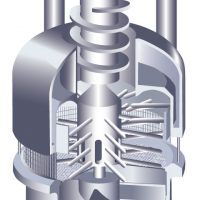

- Interchangeable single-arm sweep and helical sweep design

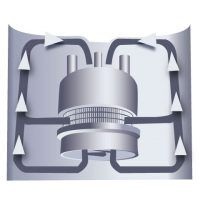

- Keeps the side wall clear and improves heat transfer

- Ideal for high viscosity products

- Patented auger feeds high viscosity materials through the mill

- Sweep easily removed for batch flexibility

- Heat transfer is improved dramatically

- One-step process means easier cleaning and less labor

- Requires minimal operator interface

- Processes very high particle solids-concentrate batches to improve milling efficiency

- Patented sweep design simultaneously compresses and scrapes material against the tank wall to assist in deagglomeration and heat transfer

- Safer; faster and greener than 3-roll mills

- Ideal for: Thixotropic; Newtonian; High Density; Heat Sensitive products

Covered by one or more of the following patents: 5,184,783; 5,497,948; 5,820,040; 7,175,118; 7,559.493; 7,828,234; 7,883,036; 7,914,200; 8,182,133; 8,376,252; 8,733,677; 9,597,691 B1

| Model | RECOMMENDED Batch Size Min/Max (Gallons) | Media Volume (Liters) |

|---|---|---|

| Micromill | .75/1.5 | 50 ML |

| HCPS - ¼ | 1.75/2 | 0.25 |

| HCPS - 1 | 8/15 | 1 |

| HCPS - 2.5 | 20/32 | 2.5 |

| HCPS- 5 | 35/55 | 4.5 |

| HCPS - 10 | 70/100 | 8 |

| HCPS - 20 | 150/220 | 18 |

| HCPS - 40 | 330/400 | 35 |

| HCPS - 60 | 430/550 | 46 |

| HCPS - 80 | 600/935 | 63 |

Read our article The High Viscosity Immersion Mill to learn more about the HCPS.

Product Documents

Video & 3D gallery

-

Hockmeyer HCPS-20 Immersion Mill

Image Gallery

Services

-

Stock Machines & Tanks NEW & USED

Our dedication to customer satisfaction doesn’t stop with the purchase.

-

Field Training & Support

Hockmeyer is dedicated to providing best-in-class support to maintain the lifespan and efficiency of your Hockmeyer equipment.

-

Equipment Support Program

Learn about how Hockmeyer can provide dedicated service, maintenance, and training through our Equipment Support Program.