Features & Specifications

Immersion Milling Innovation at Its Best

Machine Features

- Flexibility for various batch volumes

- Hook up to any tank: portable or permanent

- Sanitary fittings for fast and easy cleanup

- High screen surface area to media ratio

- Greater media field throughput than any mill on the market

- Nanoparticle size capability

- Easy cleanup and minimal waste with 99% product recovery

- Wide range of screen sizes is available

- Handles slurry up to 15,000 cps

| Model | recommended Batch Size Min/Max (Gallons) for maximum efficiency | Media Volume (Liters) |

|---|---|---|

| Micromill | 1 L/1 Gal. | 49 ML |

| HNG-1 | 5/20 | 1 |

| HNG - 2.5 | 15/50 | 2.25 |

| HNG - 5 | 35/100 | 4.5 |

| HNG-10 | 50/125 | 8 |

| HNG - 20 | 150/400 | 18.5 |

| HNG - 60 | 400/1000 | 46 |

DEAERATION: THE EFFECTS OF VACUUM

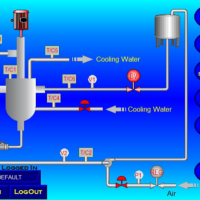

While milling under vacuum, small amounts of air entrapped gas bubbles within the agglomerates begin to expand and push apart the solids. The air separates from the solids and begins to accumulate in the mill’s upper chamber. Once enough air accumulates, it is purged intermittently by the mill, returning to the supply tank and quickly rising to the top where it is released.

Learn how the HNG's Vacuum Milling Enables Purer, Faster Dispersions

Covered by one or more of the following patents: 5,184,783; 5,497,948; 5,820,040; 7,175,118; 7,559.493; 7,828,234; 7,883,036; 7,914,200; 8,182,133; 8,376,252; 8,733,677; 9,597,691 B1

Product Documents

Video & 3D gallery

-

HOCKMEYER MILLING TECHNOLOGY - NEXGEN RECIRCULATING VACUUM MILL

-

NEXGEN™ Vacuum Recirculation Mill

Image Gallery

Services

-

Stock Machines & Tanks NEW & USED

Our dedication to customer satisfaction doesn’t stop with the purchase.

-

Field Training & Support

Hockmeyer is dedicated to providing best-in-class support to maintain the lifespan and efficiency of your Hockmeyer equipment.

-

Equipment Support Program

Learn about how Hockmeyer can provide dedicated service, maintenance, and training through our Equipment Support Program.