Industry Information

Media Mills Explained: Types, Benefits, and Industrial Applications

From paints and inks to pharmaceuticals and battery slurries, achieving the right particle size and uniform dispersion can make or break performance. The workhorse behind many of these results? The media mill.

Every media mill relies on tiny grinding media (beads) to reduce particle size through impact and shear, but designs and operating methods differ—and those differences show up in efficiency, cleanliness, energy use, and final product quality.

This guide explains what a media mill is, compares major types (including Hockmeyer’s HCP Basket/Immersion mills and NEXGEN™ Vacuum Recirculation mills), outlines core benefits, maps common industrial applications, provides a simple cost–benefit framework, flags pitfalls to avoid, and closes with a practical worked example.

What Is a Media Mill?

Definition

A media mill is a wet grinding and dispersion device that uses small spherical media, often in the 0.3–2.0 mm range, within a moving slurry to reduce coarse or agglomerated particles to micron or sub-micron sizes.

Core Functions

- Improve dispersion quality (break down agglomerates)

- Reduce particle size

- Tighten particle size distribution (PSD)

- Enhance product performance (color strength, gloss, stability, reactivity, bioavailability)

Why It Matters

- Critical product attributes such as stability, appearance, flow, and electrode performance, depend on controlled PSD.

- Regulatory and customer expectations increasingly demand repeatable, cleaner processes with consistent outcomes.

Media mill vs. high-shear mixer: High-shear mixers disperse and wet-out solids but generally cannot achieve the same fine grinding or narrow PSD that a media mill delivers.

Types of Media Mills

All types use media; geometry, flow path, and process controls determine efficiency, cleanliness, footprint, and ideal use cases.

Hockmeyer’s Media Mills

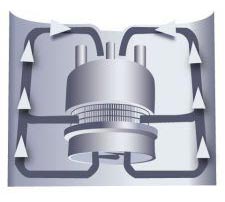

Basket (Immersion) Mills: HCP Series

- How it works: The milling basket is immersed directly into the batch, circulating the slurry through an aggressive and turbulent shear zone at very high velocity.

- Important: It still requires a disperser for pre-mix prior to milling to properly wet out and the solids and start the deagglomeration process.

- Best for: Rapid changeovers, frequent color changes, and small–to–mid batches where reduced transfers and fast sanitation matter.

Operational advantages

- Fewer vessels/valves → lower product loss and faster cleaning.

- Shorter cycle times vs. horizontal-mill trains.

- Operator-friendly loading and cleaning.

- Optimized productivity, where operators can get more out of their schedule with efficient machines.

Typical outcomes

- Faster to spec, tighter PSD, lower contamination risk.

Vacuum Recirculation Mills: NEXGEN™ Series

- How it works: Vacuum-assisted recirculation increases slurry–media contact frequency and promotes deaeration, boosting grinding efficiency and finish quality.

- Best for: High-performance targets (including sub-micron), high-value or air-sensitive products; water-based dispersions, battery slurry, pharma, and high performance coatings.

Operational advantages

- Accelerated grind times with lower energy per kg.

- Consistent sub-micron results; improved defoaming/deaeration.

- Enhanced heat management and a stable operating window.

Competitive Media Mills (for comparison)

- Horizontal Mills

- Pros: Widely available; good fine grinding; scalable.

- Cons: longer cleaning/changeovers, more transfers; slower process times in many workflows.

- Vertical Mills

- Pros: Simpler layout; manageable maintenance.

- Cons: Less efficient at ultra-fine targets; potential settling behavior.

- Attritor Mills

- Pros: Flexible batch grinding; rugged.

- Cons: Less automated; may require more hands-on oversight.

- Ball Mills

- Pros: Familiar, robust.

- Cons: VERY slow, higher energy per result; less competitive for modern fine targets; noise can be a factor.

- Vibratory Mills

- Pros: Niche materials, specialty cases.

- Cons: Less common in large-scale modern production; noise/vibration considerations.

Media Mill Type at a Glance

| Mill Type | Typical Viscosity Range | Finishing Fineness | Changeover Speed | Cleaning Complexity | Best-Fit Use Cases |

| HCP Basket (Immersion) | Low → High | Micron to sub-micron. | Fast | Low | Frequent color changes; small–mid batches; low waste. |

| NEXGEN™ Vacuum Recirculation | Low → High | NANO capable. | Medium | Medium | High-value, air-sensitive, advanced performance targets. |

| Horizontal | Low → Medium | Micron to fine. | Slow | High | Traditional lines; larger continuous runs. |

| Vertical | Low → Medium | Micron | Medium | Medium | Simpler setups; moderate fineness targets. |

| Attritor | Medium → High | Micron | Medium | Medium | Rugged batch processing, flexible formulations. |

| Ball | Low → High | Coarse to micron. | Slow | Medium | Legacy systems; non-critical fineness targets. |

| Vibratory | Varies | Niche/specialty | Slow | High | Specialty materials; R&D or limited production. |

Benefits of Media Mills

Precision Particle Size Control

Achieve micron/sub-micron results with a narrow PSD, improving color strength, gloss, stability, conductivity, and reactivity.

Improved Dispersion & Stability

Break down agglomerates, reduce settling and syneresis, and extend shelf life.

Efficiency Gains

Vacuum recirculation can boost throughput, eliminate foam, and reduce kWh/ton, while integrated designs cut steps and downtime.

Flexibility Across Viscosities

With the right design and media selection, process low-viscosity inks through high-viscosity pastes.

Scalability & Reproducibility

Match geometry and tip speeds from lab/pilot to production for predictable scale-up.

Cleaner, Leaner Processes

Fewer transfers mean less flush waste and faster sanitization/changeovers, plus improved operator safety and ergonomics.

Industrial Applications of Media Mills

- Paints & Coatings: Achieve color strength, gloss, and haze control; compatible with low-VOC waterborne systems.

- Printing Inks: Support high pigment loading and stability for digital, flexo, and gravure. Can reach nano range for digital inks

- Cosmetics & Personal Care: Deliver smooth sensory profiles, stable emulsions, and uniform pigments.

- Pharma & Biotech: Reduce particle size to improve solubility/bioavailability; disperse excipients and film-coating systems.

- Agrochemicals: Produce suspension concentrates (SCs) and stable emulsions; mitigate settling.

- Food & Confectionery: Create consistent flavor dispersions, smooth texture, colors, and emulsified systems.

- Ceramics & Minerals: Control slurry rheology for advanced ceramics, coatings, and polishing compounds.

- Energy & Batteries: Prepare cathode/anode slurries; uniformly disperse conductive additives; manage gas entrainment.

Quick mapping (examples):

| Application Area | Key Objective | Recommended Mill Type(s) | Typical Media Size Range |

| Paints & Coatings | Gloss, color strength, stability. | HCP Basket; Horizontal; NEXGEN™ | 0.5–1.0 mm |

| Printing Inks | Opacity, tight PSD, nano | HCP Basket; NEXGEN™ | 0.3–0.8 mm |

| Cosmetics | Uniform pigments, smooth feel. | HCP Basket; NEXGEN™ | 0.3–1.0 mm |

| Pharma Suspensions | Bioavailability, narrow PSD. | HCP Basket; NEXGEN™ (vacuum benefits) | 0.3–0.6 mm |

| Agrochemicals (SCs) | Anti-settling, stable dispersions. | NEXGEN; Horizontal | 0.5–1.2 mm |

| Batteries (Li-ion) | Sub-micron, deaeration control. | NEXGEN™ Vacuum Recirculation | 0.3–0.6 mm |

(Media sizes are general ranges; optimal selection depends on formulation, target fineness, and rheology.)

Cost–Benefit Framework (Worksheet Preview)

Direct Costs

- CapEx: Equipment

- Consumables: Grinding media, pegs, screens, seals

- OpEx: Energy, parts/maintenance, cleaning/flush materials, operator time

Direct Benefits

- Cycle time reduction, higher throughput, improved first-pass yield, lower kWh/ton, reduced flush waste.

Qualitative Benefits

- Cleanability, fewer transfers, operator ergonomics, regulatory alignment (sanitation, emissions), lower contamination risk.

ROI formula (plug-and-play):

ROI = (Hours saved × Labor rate) + (Waste reduced × Unit cost) + (Yield gain × Margin) − (CapEx amortization + OpEx)

Worksheet inputs

- Avg. batches/month; batch size (kg or L).

- Current cycle time vs. target cycle time.

- Energy cost/kWh; current vs. projected kWh/ton.

- Flush waste per changeover (kg) and material cost/kg.

- Media wear rate and replenishment cost.

- Operator hours/batch; labor rate.

- CapEx amortization horizon (years).

Hidden Pitfalls to Avoid

- Media mismatch: Wrong size/density/material yields poor impact/shear, bead breakage, or contamination.

- Filling errors: Over/under-filling the chamber or basket reduces efficiency, increases heat, and risks screen blinding.

- Viscosity misfit: Selecting a mill that doesn’t match rheology inflates energy use and time-to-spec.

- Thermal management: Inadequate cooling can cause degradation, color shift, or gelation.

- Seal & wear oversights: Neglecting mechanical seals, screens, or shaft runout invites contamination and downtime.

- Cleanability & cross-contamination: Underestimating changeover needs in multi-color/product facilities leads to yield loss.

Quick checklist: Media spec ✓ | Fill level ✓ | Tip speed ✓ | Cooling capacity ✓ | Seal condition ✓ | Screen condition ✓ | CIP/SIP plan ✓

Worked Example (Teaser)

Scenario: A coatings producer requires D90 ≤ 5 μm with a narrow PSD.

Legacy train: disperser + horizontal mill; ~10 hours total; multiple transfers; two flush cycles.

Switch to HCP Basket (Immersion):

- ~3 hours total; one-vessel workflow; ~70% time saved; the process still uses a disperser for pre-mix before immersion milling.

- Flush waste -reduced due to fewer transfers.

- Improved repeatability across shifts (tighter PSD).

Optional enhancement: For sub-micron targets and deaeration-sensitive systems, a NEXGEN™ Vacuum Recirculation mill can further reduce cycle time and improve finish consistency.

Conclusion

A media mill is essential for producing fine, stable dispersions across a wide range of industries. Design differences, basket vs. vacuum recirculation vs. traditional geometries, have outsized impact on cycle time, cleanliness, PSD, and energy. Hockmeyer’s HCP Basket (Immersion) and NEXGEN™ Vacuum Recirculation mills represent next-generation options for teams prioritizing fast changeovers, consistent fine finishes, and clean, efficient operations.

Ready to evaluate options for your process?

- Request lab/pilot testing to validate results on your formulation.

- Use the Media Mill ROI Worksheet to quantify the business case.

- Consult an engineer to align mill type, viscosity, target PSD, and sanitation requirements with production goals.