Industry Information

How to Choose the Right High-Viscosity Mixing Equipment

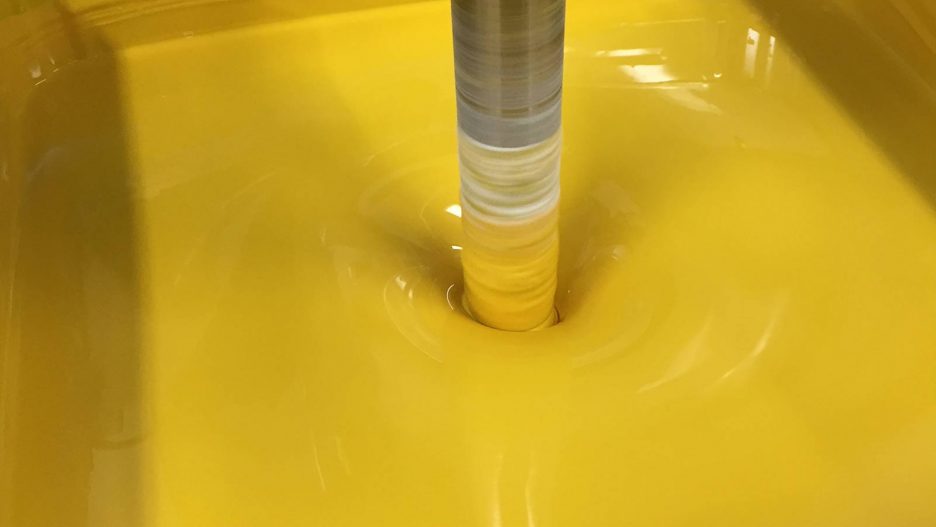

When combining highly viscous materials that wouldn’t typically be blended together into a uniform substance, and dispersing powders into high viscosity liquids, selecting the right high-viscosity mixing equipment is essential to the success of your product. Why? Because with challenging materials like these, achieving uniformity is often difficult, and that uniformity (or lack thereof) can have a significant impact on the performance, stability, and durability of the resulting product.

Horizontal Mixer: Rugged Efficiency That Gets the Job Done

Looking for a sturdy, efficient mixer to handle large volumes of highly viscous materials? Hockmeyer’s Horizontal Paste Mixer features triple mixing blades for uniform wetting and fast mixing of even the toughest materials, as well as a specially designed impeller that follows the contours of the tank precisely to help eliminate “dead” spots. Additionally, Hockmeyer’s jacketed tanks can be used to ensure uniform temperature control when producing high-temperature industrial processing applications. These jackets create an excellent temperature transfer for thermal fluid operations, establishing temperature control within the batch, and have the capability of being divided into multi-pass zones to increase process flexibility.

This mixer’s overlapping arms prevent material buildup, while the double rolling action of the blades moves the material against the side of the tank for excellent shear (the relative movement of adjacent layers in a liquid or plastic during flow) and wetting (the interaction between the surface of a liquid and the surface of a solid or another liquid). As a result, the Horizontal Paste Mixer is ideal for everything from adhesives, sealants, and printing inks, to polyesters, ceramics, pharmaceuticals, and more. Plus, in addition to durability and efficiency, this mixer requires less power than similarly sized machines since no motion is wasted during the blending process.

HHL-III Triple Shaft Mixer / Disperser: Low Speed and High Speed Blades Work Together to Ensure Uniform Mixtures

Hockmeyer’s next high viscosity mixing solution? Multi shaft mixers like the HHL-III Triple Shaft Mixer/Disperser. To ensure the proper dispersion of highly viscous materials, Hockmeyer’s multi-shaft mixers have a center mounted low speed helical or anchor blades which sweep the mixing vessel wall and one or more high-speed dispersion shafts, which provide shear to disperse or dissolve ingredients. Triple-shaft mixers like the HHL-III are most often used to mix medium to high viscosity products, and are typically used when making materials like sealants, caulks, magnetic media slurry, creams, and more.

Wondering why low speed blades are an essential feature of this mixer? Using low speed to assist in effectively mixing materials may seem counterintuitive, but the low speed blade feeds the high-speed dispersion blade(s) by blending and folding the mass in the vessel to improve product uniformity, while the patented scrapers provide excellent heat transfer and aid in powder incorporation.

Another benefit of multi-shaft mixers like the HHL-III Triple Shaft Mixer is their use of bi-directional teflon scrapers. The scrapers are stacked on top of each other in a continuous row, creating complete coverage of the sidewall and bottom of the tank. Additionally, high-speed dispersers alone have a limited zone of influence in viscous products, so the low-speed blade is necessary to achieve a uniform, well-blended mixture.

HHL-II Dual Shaft Mixer / Disperser: Easier Maintenance with Excellent Performance

Like the HHL-III Dual Shaft Mixer/Disperser, the HHL-II utilizes a center-mounted low speed helical or anchor blade, which ensures accurate dispersion by sweeping the mixing vessel wall and a high-speed dispersion shaft to ensure proper dispersion. Dual shaft mixers, like this one, are most often used to mix medium to very high viscosity products, and are used in the making of printing inks, caulks, hot melt adhesives, lotions, toothpaste, and more.

One benefit of the Dual Shaft configuration is that it will handle most multi-shaft mixing jobs. As a result of its separate mixing shafts, maintenance is easier on a Dual Shaft mixer than on a Concentric Shaft mixer. Plus, like the HHL-III Triple Shaft Mixer, bi-directional teflon scrapers can aid in heat transfer and provide coverage of the entire sidewall and bottom of the tank.

Additional Areas for Consideration When Selecting a High Viscosity Mixer

Before you make your decision on which High Viscosity Mixer is right for your needs, there are a few additional factors to consider. First, it’s essential to understand what exactly you’re trying to achieve with your high viscosity mixer. Typically, uniformly blending two or more ingredients is the reason for mixing. That being said, there are a multitude of factors that play into how uniformity is achieved for your specific product, including the times and techniques of loading, mixing, cleaning, discharge, machine maintenance downtime, power consumption and the design of the mixer itself. Before you choose a high-viscosity mixer, you’ll need to carefully review the effectiveness of the whole mixing system, not just the mixer’s performance.

Next, think through the economic impacts of your choice. While everyone would love to own the most effective “dream” mixing system, oftentimes that “dream system” may not be the most economical choice. A system’s projected profitability and length of time the product may be in demand must be matched against not only the capital and operating costs of the system, but also the anticipated start-up time required with such a system. Additionally, alternative use and resale value of the equipment should be considered.

Ultimately, the truth is that there is no one mixer that can satisfy all mixing needs. While viscous mixing isn’t simple, it can be made easier by understanding the basics of mixing, pinpointing your particular needs, and asking the right questions. Whatever your needs are, Hockmeyer machines have a reputation for performance and reliability, thanks to our decades of experience in the industry and our commitment to innovation. Our high-viscosity mixers are designed by an experienced engineering staff incorporating information from customers, our own R&D Laboratory and years of data from Hockmeyer multi-shaft mixers.

Ready to learn more, or looking for advice? Our team is here to help.