Industry Information

Recirculation vs. Immersion Mills: Choosing the Right Milling Technology

Selecting the right milling technology is rarely a straightforward decision. When evaluating recirculation vs. immersion mills, engineers and manufacturers must balance multiple process demands simultaneously. In wet grinding and dispersion applications, this choice directly influences product quality, processing efficiency, and long-term operational performance.

Recirculation mills and immersion mills offer distinct advantages depending on material, batch size, viscosity, and production objectives. Choosing the wrong approach can lead to inconsistent dispersion, extended processing times, or unnecessary operational complexity.

This guide provides a practical, process-driven comparison of immersion vs. recirculation mills. Rather than positioning one solution as universally superior, the goal is to clarify how each technology functions, where it excels, and how to align mill selection with real-world production requirements. By understanding these differences, manufacturers can make informed decisions that support consistency, efficiency, and scalable production.

Understanding Recirculation Milling Technology

Recirculation milling is a controlled batch process designed to deliver consistent, repeatable particle size reduction through repeated material circulation. In a recirculation system, material is pumped from a holding vessel through a media mill and then returned to the vessel. This loop continues until the desired particle size distribution (PSD) is achieved.

Within the mill chamber, grinding media, rotating and stationary pegs, and screens apply high, uniform energy to the material. Because the product repeatedly passes through the milling zone, recirculation mills offer precise control over residence time and energy input. This level of control makes recirculation milling particularly effective for applications requiring fine grinding and tight PSD tolerances.

One of the defining advantages of recirculation milling is process consistency. By controlling flow rate, media loading, and milling duration, operators can fine-tune dispersion quality with high repeatability. This is especially valuable in formulations where small variations in particle size can affect stability, color strength, or product performance.

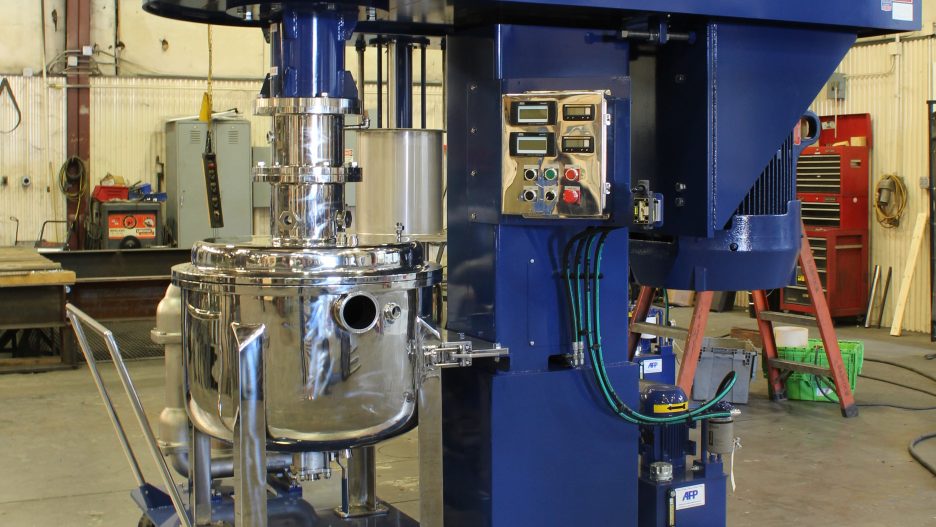

Hockmeyer’s NexGen Vacuum Recirculation Mill introduces an additional process advantage by operating under vacuum. Removing entrained air from the liquid during milling minimizes foaming and bubble formation, both common challenges in water-based formulations. Bubbles can act as a “cushion”, impeding particle-to-particle impact and prolonging process time. Vacuum operation improves dispersion efficiency while enhancing finished product quality, particularly in coatings, inks, and other air-sensitive systems.

Recirculation mills also provide flexibility across a wide range of batch sizes. While recirculation is not a continuous process, it remains a highly controlled batch operation optimized for throughput and repeatability. Typical applications include fine pigment grinding, agricultural suspensions, advanced dispersions, and formulations requiring uniform quality at scale.

Understanding Immersion Milling Technology

Immersion milling takes a different approach by processing material directly within the batch vessel. An immersion mill is lowered into the product, where it generates high shear forces through a rotating media chamber with pegs and screens. Material is drawn into the mill, processed, and immediately returned to the surrounding batch.

This in-vessel design makes immersion mills highly versatile and well-suited for batch-oriented production environments. Because the mill operates directly in the vessel, there is no external pumping loop or recirculation piping. This simplified setup reduces system complexity while improving accessibility and ease of operation.

One of the primary advantages of immersion milling is flexibility. Immersion mills can process a wide range of viscosities and solids loadings, making them ideal for high-viscosity formulations such as high solids dispersions, adhesives, sealants, mastics, and specialty coatings. These systems are also well-suited for operations with frequent product changeovers, as they are easy to clean and reconfigure between batches.

From a development perspective, immersion milling simplifies scale-up from lab to production. Process parameters established during testing can often be transferred directly to larger systems with minimal adjustment. This supports faster commercialization while reducing scale-up risk. For manufacturers prioritizing batch flexibility and operational simplicity, immersion milling remains a reliable solution.

Key Differences Between Recirculation and Immersion Mills

Understanding the operational differences between recirculation mills and immersion mills is critical when evaluating process performance.

Process Flow and Residence Time

Recirculation mills rely on controlled material flow through an external milling chamber, enabling precise control of residence time. Immersion mills process material directly within the vessel, where residence time is influenced by batch mixing dynamics rather than pump-driven flow.

Energy Delivery

Recirculation systems deliver uniform energy input across multiple passes, supporting tighter PSD control. Immersion mills generate localized high shear within the vessel, offering effective dispersion across a broader viscosity range.

Throughput and Consistency

Recirculation milling supports high throughput for large batches while maintaining consistency. Immersion milling prioritizes flexibility and responsiveness, particularly for smaller or variable batch sizes.

System Complexity and Footprint

Recirculation systems require pumps, piping, and external chambers, increasing system complexity. Immersion mills feature a more compact, integrated design that simplifies cleaning and maintenance.

Application-Specific Recommendations

Choosing between recirculation and immersion mills should be guided by formulation behavior and production goals.

Low- to medium-viscosity, water-based formulations with tight PSD requirements often benefit from vacuum recirculation milling, especially when air entrainment or foaming is a concern. High-viscosity formulations or systems with high solids loading typically perform better with immersion milling due to its in-vessel shear generation and sweep blade option.

Batch size also plays a role. Recirculation mills are well-suited for large batch volumes requiring consistent quality across production runs. Immersion mills excel in batch-driven environments with frequent changeovers.

Common industries benefiting from vacuum recirculation milling include specialty coatings, inks, agricultural formulations, and advanced dispersions. Immersion milling is widely used in the production of paints, adhesives, sealants, cosmetics, and specialty chemicals.

Decision Framework for Selecting the Right Milling Technology

The questions below create a more complete, decision-ready framework:

1) Define the end requirement: quality and performance

- What particle size distribution is required, including target size, distribution width, and allowable variance?

- Is the goal primarily deagglomeration, true particle size reduction, or a combination of both?

- Which downstream properties are sensitive to particle size distribution, such as stability, color strength, gloss, rheology, filtration, or sprayability?

2) Characterize the formulation and what the mill must tolerate

- What viscosity range will the material experience across the process, from initial mixing through final milling?

- What solids loading is required, and how hard or abrasive are the particles relative to media selection and wear?

- Is the formulation shear-sensitive, with potential risks such as polymer damage, viscosity loss, or heat sensitivity?

- Is the system water-based, or prone to foaming or air entrainment that could affect dispersion quality?

3) Align with production realities and how the plant actually runs

- What are the typical batch sizes, and how frequently do they change?

- Is the process optimized for time to specification, overall throughput, or fast changeover?

- How often do product changeovers occur, and what level of cleaning validation is required?

- What utility or infrastructure constraints exist, including pump capacity, floor space, available power, ventilation, or noise limits?

4) Determine the control strategy and required process precision

- How critical is residence time control and repeatable energy input to achieving consistent results?

- Is tighter control over temperature rise during milling required to protect product quality?

- What level of instrumentation is needed, such as flow, pressure, temperature, vacuum control, or particle size monitoring?

- Who will operate the system, and how much process robustness is needed to accommodate varying operator skill levels?

5) Evaluate risk, scale-up potential, and total cost of ownership

- What are the consequences of producing off-spec material, including scrap, rework time, or customer rejection?

- How easily can process parameters be transferred from lab or pilot scale to full production?

- What wear and maintenance factors should be considered, including media wear, seals, and cleaning time?

- What return on investment is expected in terms of reduced cycle time, improved consistency, lower downtime, and fewer off-spec batches?

Decision guidance: Where do these answers typically point to?

- When tight particle size control, predictable energy input, and repeatability at larger batch volumes are required, vacuum recirculation milling is often the stronger fit, particularly when foam or air entrainment is a known issue in water-based systems.

- When high batch flexibility, simpler setup, frequent changeovers, and strong performance in higher-viscosity formulations are priorities, immersion milling is often the better match.

Balancing flexibility, control, and throughput is essential. Pilot testing and validation remain critical steps in confirming equipment selection, as testing allows manufacturers to evaluate dispersion quality, processing efficiency, and scalability before committing to full-scale implementation. Hockmeyer supports this process with applications-focused testing, helping teams validate milling performance and process parameters before scaling to production.

Selecting the Optimal Milling Solution with Confidence

The choice between recirculation and immersion milling technologies is fundamentally application-driven. Both approaches offer proven performance, but each serves different process priorities. Recirculation mills deliver controlled, repeatable results for fine grinding and larger-batch processing, while immersion mills offer flexibility, simplicity, and rapid batch turnover.

Understanding the strengths of recirculation vs. immersion mills enables manufacturers to select equipment that aligns with material characteristics and production objectives. If you’re ready to purchase a system or need additional information to make a confident decision, contact Hockmeyer’s process engineers to schedule product testing and evaluate recirculation or immersion milling performance before scaling to production.

With decades of wet grinding expertise, Hockmeyer supports customers through testing, optimization, and customized equipment solutions, helping engineers make confident, data-driven milling decisions from development through full-scale production.