Equipment for Milling, Mixing, and Dispersion for Agricultural Chemicals

In agricultural chemical manufacturing, achieving optimal particle size is crucial for enhancing the efficacy and efficiency of active ingredients. When applied to crops or pests, smaller particles offer improved dispersion, coverage of a larger surface area, and enhanced bioavailability. Hockmeyer mixers ensure uniform distribution of components’ particles in chemical formulations, incorporating liquids and solids for consistent quality. Hockmeyer mills aid in uniformly dispersing additives in formulations, enhancing performance, and reducing environmental impact. They are vital for reducing pigment size in seed coatings and refining active ingredient sizes for fertilizers, pesticides, and herbicides.

Need Help? Contact Us Today!

-

Headquarters

-

Parts & Service

Industry Benefits

Crop Nutrition

Finely milled particles may have better flowability and dispersibility, making them easier to apply uniformly to the soil. This enhanced consistency can improve nutrient distribution in the root zone and better effectiveness when applied to crops.

Mulch & Grass Colorants

Properly milling mulch and grass colorants contributes to a more uniform and even particle distribution, leading to consistent coloration when applied to mulch or grass surfaces. This allows for more vibrant and long-lasting colors when applied and reduces settling and agglomeration of colorant particles, preventing issues such as the clogging of application equipment and costly poor pigment yields.

Pesticides

Milling pesticides increases the surface area of active ingredients, leading to better dispersion, easier mixing, and more efficient contact with target pests. Additionally, finely milled particles create fine droplets, improving spray coverage and penetration into target areas, leading to improved pesticide formulations and better pest control overall.

Fungicides

Reducing particle size is beneficial in fungicides since smaller particles increase the surface area available for contact with fungal pathogens. Uniform coverage is more easily achieved after the fungicide is enhanced through milling since the fungicide is applied as a spray or mist thanks to finely milled particles.

Herbicides

Milling herbicides to decrease particle size extends their effectiveness and reduces the required frequency of applications to achieve desired results. The milling process is especially important in controlled-release herbicide formulations, where the active ingredients are released gradually over time.

Featured Industry Solutions

-

HCP Immersion Mill

Machine Features Multiple tank positions with 360º rotation available Minimal cross-contamination, easy clean-up, and low solvent loss Maximizes color development, strength, gloss, durability, and yield Reduction of process time versus…

View HCP Immersion Mill

-

HCPN Immersion Mill

Machine Features The HCPN Immersion Mill is the cutting edge in nanoparticle production. This revolutionary machine makes the science of nanoparticle manipulation user friendly, clearing the path to new product…

View HCPN Immersion Mill

-

HCPS Immersion Mill with Sweep Blade

Machine Features Interchangeable single-arm sweep and helical sweep design Keeps the side wall clear and improves heat transfer Ideal for high viscosity products Patented auger feeds high viscosity materials through…

View HCPS Immersion Mill with Sweep Blade

-

MICRO MILL

Machine Features Disperser and Immersion Mill capabilities Temperature readouts with programmable auto shut-offs Electronic height adjustments Adjustable time with automatic stops Speed controls Tip speed readouts Jacketed cooling vessels

View MICRO MILL

-

NEXGEN™ MICRO MILL

Machine Features Mill and deaerate at once Greatest throughput of all media mills on the market Nano-particle size capability Media size as small as .03mm Sanitary fittings for fast and…

View NEXGEN™ MICRO MILL

-

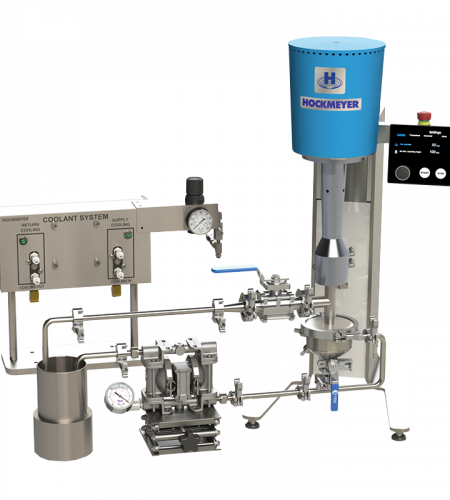

NEXGEN™ Vacuum Recirculation Mill

Machine Features Flexibility for various batch volumes Hook up to any tank: portable or permanent Sanitary fittings for fast and easy cleanup High screen surface area to media ratio Greater…

View NEXGEN™ Vacuum Recirculation Mill

-

NEXGEN™ Vacuum Rotor Stator

DISPERSION TECHNOLOGY. FAST. PATENTED The process takes place in a temperature-controlled environment to preserve formulae characteristics and function. A thorough cooling system covering the chamber and return lines quickly mitigates…

View NEXGEN™ Vacuum Rotor Stator

Why Choose Hockmeyer

Better Milling, Mixing, and Dispersions for Agricultural Chemicals and Formulations

As an industry leader and trusted partner for many in the industry, the Hockmeyer team understands the importance and impact of innovative equipment for particle size reduction, dispersion, mixing, and other process requirements. Thanks to the company’s wide variety of industry-leading equipment and extensive experience, Hockmeyer also has a remarkable history of excellence in customer satisfaction and innovation for businesses seeking solutions in milling agricultural chemicals.

Test Your Product Free. Schedule a Test Today!

At Hockmeyer, we're committed to making your product the highest quality possible, whether you need milling, mixing, dispersion or agitation. Schedule your product to be tested in one of our demo machines and see the Hockmeyer difference for yourself.

Services

-

Field Training & Support

Hockmeyer is dedicated to providing best-in-class support to maintain the lifespan and efficiency of your Hockmeyer equipment.

-

Equipment Support Program

Learn about how Hockmeyer can provide dedicated service, maintenance, and training through our Equipment Support Program.

-

Customer Testing-Applications Lab

Don’t trust promises, trust results! Hockmeyer offers it’s Customer Service Laboratory to show you exactly how our equipment will increase your product quality and efficiency!

Agricultural Chemical Manufacturing Frequently Asked Questions

-

How can Hockmeyer’s equipment assist in the agricultural chemical manufacturing process?

Hockmeyer equipment suits various batch sizes, accommodating small-scale research and large-scale production for agricultural chemicals. This scalability aids testing and meets market demand. Our mills disperse additives uniformly, enhancing efficacy. Designed for reliability, repeatability, and safety, the equipment ensures consistent quality, meets specifications, and saves time and resources for manufacturers.

For more information, read our article that details the benefits of particle size reduction in agrochemicals.

-

What equipment is ideal for agricultural chemical milling?

Several Hockmeyer offerings perfectly suit agricultural chemical milling, including the Micro Mill, NexGen™ Micro Mill, HCP Immersion Mill, and NexGen™ Vacuum Recirculation Mill. Hockmeyer’s HCP and NexGen™ Mills provide manufacturers with a temperature-controlled mill chamber, a tank (and recirculation lines) for sensitive products and processes, and efficient milling to nano-size particles with media as small as 0.03 mm. With these innovative machines, manufacturers can achieve higher yields with nanoparticles, which allow for more targeted delivery and can increase the active ingredient yield and efficacy in agricultural chemicals.

-

Is there testing available for Hockmeyer equipment for agricultural chemical product manufacturing?

Absolutely! While agricultural chemical product manufacturing is not a simple process, it can be made easier by applying scientifically confirmed test results. That’s why we encourage manufacturers to perform trials at our Customer Service and Testing Facility, where customers are encouraged to run tests and work with our team of experts, and make initial testing free.

-

Can agricultural chemicals be sustainable?

Yes, while they’re often lumped together with more environmentally harmful chemicals, agricultural chemicals can be sustainable. Sustainable agricultural chemicals aim to minimize environmental harm by containing less persistent, low-toxicity compounds, preventing water contamination, and reducing chemical use and waste through precision agriculture. Green chemistry principles are also used to guide the development of safer, energy-efficient options, including biopesticides and biostimulants derived from natural sources that provide effective alternatives to traditional chemicals with reduced environmental impact.