Dispersers and Immersion Mills

High-Speed Disperser: An Updated Practical Guide

Updated on September 30, 2022: Thanks to popular demand, we’ve updated this guide to high-speed dispersers to serve as a helpful resource for newcomers to high-speed dispersion equipment. Read on to find out what you need to know about high-speed dispersers as you work to become better acquainted with their ins and outs.

Every year, new people join the various businesses that use high-speed dispersion equipment in their laboratories and manufacturing facilities. What seems obvious to experienced personnel can be complicated and frustrating to newcomers. The purpose of this guide is to present a fundamental explanation of the “what, how, when, and why” of high-speed dispersers. This guide is dedicated to those newcomers who will become the experts of the future.

What Is a High-Speed Disperser?

A high-speed disperser is a type of mixer used to rapidly break apart lumps of powder material, uniformly distributing and wetting them in a liquid. It is also used to dissolve soluble solids in a liquid.

How Does a High-Speed Disperser Work?

A high-speed disperser works on the principle of energy transfer. A disc-type blade is mounted at the bottom end of the mixing shaft and rotated at a relatively high tip speed. Tip speed is the speed at the outer tip or edge of the rotating disc. Tip speeds typical of high-speed dispersers are measured in feet per minute, calculated by multiplying the constant 3.14 times the diameter in feet of the disc times the revolutions per minute of the mixing shaft. The industry term for tip speed is peripheral velocity.

The solids and liquids are drawn into the rotating disc by the suction it creates. This suction usually results in a visible whirlpool from the top of the mixture down to the top of the disc. A similar whirlpool is created below the disc, extending from the bottom of the tank to the underside of the disc. The whirlpools are actually two individual vortices, although common industry practice refers only to the visible upper one as the vortex.

When the solids/liquid mixture enters the vortices and is sucked into the high-speed disc, the energy (horsepower used to drive the disc) is instantaneously transferred from the disc to the mixture. This intensely focused energy transfer creates tremendous, instantaneous velocity changes in the mixture as it progressively contacts the disc. Think of the mixture as a series of individual horizontal layers descending downward from the top and upward from the bottom onto the face of the rotating disc. As each layer contacts the disc, it is instantaneously accelerated from the slow-moving vortex into the high speed of the disc and projected outward away from the disc and toward the wall of the tank. The rapid tearing apart of layer upon layer of the mixture is shear force, commonly referred to as shear.

What Is the Difference Between a High-Speed Disperser and an Agitator?

Both the disperser and the agitator will mix. Mixers are sometimes compared to pumps. The performance of a pump is usually measured in the horsepower (HP) required for its gallons-per-minute discharge capacity. A high-speed disperser is a high-powered, low-volume pump. Considering its substantially higher horsepower per gallon requirement, a disperser is an inefficient mixer. An agitator is a low-powered, high-volume pump—it is an efficient mixer. A typical dispersion application (such as dispersing pigment to make paint) requires about 1 HP for every 10 gallons; in contrast, an agitator application (such as thinning the pigment dispersion with solvent) requires about 1 HP for every 100 gallons. Although the agitator is the more efficient pump, it does not create sufficient shear to disperse most solids into the liquids.

Moderate-shear high-speed dispersers operating at about half the normal blade speed of high-shear dispersers are sometimes used in place of agitators when some shear is required. Typically, the discs have larger teeth to promote better pumping and require about a third of the horsepower of a high-shear disperser but still three times more than an agitator.

When Do I Need to Use a High-Speed Disperser Rather Than an Agitator?

A high-speed disperser will generate the shear force necessary to rapidly de-lump powders in a liquid. This de-lumping process is called dispersion. The agitator is an efficient mixer, but it typically cannot generate sufficient shear to disperse powders, regardless of how long they are mixed. This is because the forces holding the agglomerates (lumps) together are stronger than the force of the mixer trying to pull them apart. Mixers can do an excellent job of holding dispersed (sheared) mixtures in suspension, but they typically cannot disperse (shear) the mixture.

You can learn more about this topic and the differences between high-shear mixing and homogenizing from this article, which highlights the pros and cons of both processes.

What Are the Limitations of a High-Speed Disperser?

The limitations of high-speed dispersers are product rheology dependent. That means much has to do with the flow characteristics of the product being dispersed. If it is too thick, it will not move freely to and from the blade from the wall of the tank—hence dead zones of undispersed materials in the tank. If it is too thin, there may not be sufficient body to generate tearing between the layers of product as they consecutively contact the rotating disc. Tacky or “sticky” products may also hinder the blade’s ability to generate proper flow within the tank. Proper flow should resemble a doughnut, with the blade acting as the hole. Product should flow in a circumferential pattern around the tank wall while simultaneously rolling inward to contact the blade. This type of flow is sometimes referred to as a “doughnut roll.” If undispersed particles stick to the walls of the tank or the flow is insufficient to roll the entire dispersion into the blade, a thorough dispersion is unachievable. Without flow, there is no “go.”

Our range of high-shear mixing equipment maximizes the impact of the high-speed dispersion process and includes state-of-the-art blades, such as our F-Blade. This powerful blade is interchangeable with all other manufacturers’ standard high-shear blades and, in fact, will last much longer and produce more shear and pumping action. Another excellent option is our D-Blade, also known as the “Ring” blade. This blade is a patented Hockmeyer innovation and an excellent choice for high-speed dispersion because it can handle the toughest pigment agglomerates, rapidly dissolves resins, gums, and similar materials.

What Different Types of High-Speed Dispersers Are Available, and Which Type Is Best for Me?

High-speed dispersers are available with single-speed, two-speed, and variable-speed mixing shafts. Some are directly mounted atop a tank and are fixed to operate with the blade in only the original mounting position. Other tank-mounted dispersers can raise and lower the blade by several feet (to better control the vortex) without exiting the tank.

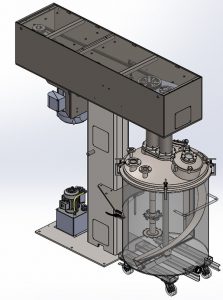

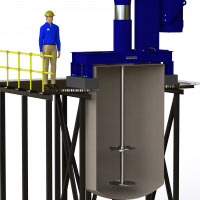

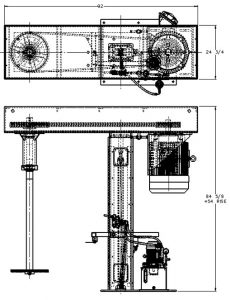

Another design, perhaps the most popular, places the disperser on top of a hydraulic lift, similar to the ones used at gas stations to lift automobiles, that is mounted to the floor. The lift enables the operator to raise the blade completely out of the mixing vessel and change to another vessel. This technique uses small portable tanks (up to 500 gallons) that can be rolled away on wheels or picked up with a fork truck. Larger stationary tanks are often centered within the arc of rotation from the center of the hoist to the center of the mixing shaft.

The bridge containing the mixing shaft at one end and the motor at the other is then rotated from one tank to the next. Choosing the best configuration of available designs is a combination of functional need and economic justification. An experienced process engineer or consultant familiar with dispersers is a good investment.

High-Speed Dispersers Available From Hockmeyer

Whatever your needs may be, our line of high-speed dispersion equipment is designed by an experienced engineering staff and combines feedback and information from customers, our own R&D Laboratory, and years of data from Hockmeyer machines. We’ve linked a few of our most popular offerings below so you can explore them and gain a sense of the tools we are able to provide to you.

- NEXGEN™ Vacuum Rotor Stator

- HVI Hoist Mounted Disperser

- Rotor Stator

- HVIE Hoist Mounted [Economy] Disperser

- Drum Mixers

Common High-Speed Disperser Questions

How Do I Select the Proper Size of High-Speed Disperser?

The size of a high-speed disperser is generally thought of in terms of horsepower. However, there are dispersers that are dimensionally very large but use relatively small amounts of horsepower. These are exceptions to the rule.

The horsepower of the disperser is related to the blade diameter and the anticipated load the blade will create at a given speed and resistance. The resistance is a function of the rheology of the dispersion as well as the viscosity and density. However, as the blade diameter increases, the horsepower increases disproportionately. For example, if a 12-inch diameter blade were to draw 20 HP in a non-Newtonian system (viscosity changes with shear), doubling the blade diameter could increase the HP demand by a factor of 5. That means a 24-inch diameter blade of the same design, working in the same product, would require 100 HP. The larger blade would also pump considerably more, so it would lend itself to working in a much larger (perhaps 5 times the volume) tank and producing a much greater amount of finished product in the same time period.

Horsepower requirements are interrelated with blade diameter, tank diameter, batch size, rheology, viscosity, and density. Variations outside recommended operating parameters usually result in compromises in performance, such as poor particle separation, extended dispersion times, and a decrease in quality of the finished product.

How Do I Select the Proper Size of Tank for My High-Speed Disperser?

The ideal manufacturing tank for most high-speed dispersers is slightly taller than wide. Dished or bowl-shaped bottoms aid in preventing solids from accumulating in sharp corners associated with flat bottoms. Equally as important, dished bottoms drain to the center, where a discharge valve can be installed. Flush bottom ball valves welded into the center of the dished bottoms further enhance the ease of discharge and cleaning. Optimum tank geometry is an integral part of several aspects that need be considered and are listed further on in this article.

How Do I Select the Proper Size of Blade for My High-Speed Disperser?

The blade is sized based upon the flow characteristics of the product and the desired degree of dispersion. The thicker the product, the larger the blade diameter must be in comparison to the tank diameter. Conversely, the thinner the product, the smaller the blade diameter must be in comparison to the tank diameter. This comparison is called the blade-to-tank ratio. Thick products like heavy, flowable pastes may require a .5:1 ratio. Moderate products like paint require a .33:1 ratio, and thin products like stains can work with up to a .125:1 ratio.

For example, if the blade-to-tank ratio is .33:1, and the tank diameter is 6 feet, the blade diameter would be 2 feet.

How Do I Know When It Is Time to Replace a High-Speed Disperser Blade?

Once the batch formula has been process optimized, the typical time required to reach maximum dispersion should range from 20 to 30 minutes after the last ingredients have been added. Longer times do not usually result in better dispersions and in some cases can be detrimental because of the higher batch temperatures generated by the high-shear disperser blade. As the blade begins to wear, longer and longer batch times are required to get to the optimized dispersion standard. Sawtooth-type high-speed disperser blades should be replaced once the blade tips are worn to half their original height.

What Type of Blade Works Best on My High-Speed Disperser?

high-shear disperser blades are available in a range of styles and sizes. They can be generally categorized into two groups: open sawtooth and ring type. Both categories work well when used under the proper operating conditions.

Instead of solely depending upon the face of the disc and the configuration of the sawtooth for shear and flow, much of the ring blade’s work is done hydraulically, as centrifugal force forces the product between the contoured rings, creating velocity differentials and a high-pressure zone within, then instantaneously discharging into the low-pressure area outside the rings, creating a film-splitting venturi effect. Additional heat is created as a byproduct of the higher shear. However, in some cases, this higher shear level eliminates or greatly reduces any subsequent milling that may have previously been required.

What Other Factors Affect the Performance of My High-Speed Disperser?

Formulating for a high-speed disperser is an important part of reaching optimum dispersion.

Optimizing a formula can sometimes have more to do with how and when ingredients are added, since basic recipe changes may not be acceptable. In most instances, rapid addition of about half the total amount of powders into the liquid vehicle is acceptable, although careful observation of each initial formula is prudent to ensure powders are not floating on top of the batch for more than a few seconds. Adding dry powders too rapidly can “choke” the blade and may result in an incomplete, unstable dispersion. The last half of the powders should be added progressively more slowly, until the final percentage completes the formula. The blade speed should be adjustable from a minimum of half the final tip speed at the beginning of the powder addition to the maximum of the final tip speed as the batch thickens and flow slows. This procedure helps prevent splashing and over-vortexing, which are inefficient for dispersion and can cause excessive air entrapment in the dispersion. Assuming the rules of tank size, horsepower, blade size, etc. have been followed, most dispersions are completed within 20 to 30 minutes after the last of the powders have been properly added. Continuing the dispersion process beyond that time is usually unproductive and can actually cause harm to some ingredients if the temperature continues to rise.

Typically, high-speed dispersers perform best when the flow pattern is doughnut-shaped and the blade tips are traveling at about 5,000 feet per minute in a medium viscosity (1,500 to 5,000 centipoises). Lower tip speed may be acceptable at higher viscosities and higher tip speeds may be acceptable at lower viscosities to get to the same shear rate and stress. In other words, shear is a function of blade-tip speed and product rheology.

How Do I Operate My High-Speed Disperser for Optimum Performance?

The following is a summary of the detailed aspects outlined in the above paragraphs. Optimum performance requires the following criteria:

- Start with a clean tank

- Correct blade-to-tank ratio

- Proper formulation

- Suitable blade in good condition

- Highest appropriate blade-tip speed

- Correct tank geometry (length compared to width)

- Sufficient horsepower

- Proper technique of adding raw materials

- Proper rheology

What High-Speed Disperser Safety Measures Must I Follow and Why?

- Read the operation and safety instructions supplied by the manufacturer. If they are not available, call the manufacturer and request additional copies.

- Be certain that all operators are properly trained on the use of, and drilled on the potential dangers involved with, the disperser.

- Do not operate the machine unless all the appropriate safety features are in place and functioning properly. On hoist-mounted units that raise and lower the blade, these features include but are not limited to (a) mixing shaft guard, (b) tank holder with limit switch, (c) and limit switch on lift to prevent machine from operating with blade or shaft within reach of the operator.

The high-speed disperser is a very fast and powerful machine. Serious and fatal accidents can occur in a split second of carelessness. Human reflex is no match for the instantaneous danger of operating a disperser unsafely. Never sacrifice safety for convenience.

In Closing

If you still have questions about high-speed dispersers or would like to learn more about equipment offerings from Hockmeyer, our team is here to help. Contact us for more information about our products and how they can best serve you and your business needs or to learn more about our Test-to-Own Demo Program, which can establish the production parameters in your environment before you make a long-term commitment.