Best-in-Class Milling Equipment for Cosmetics & Personal Care Products

Innovative equipment is essential for achieving the best possible results in milling pigments for personal care products and cosmetics. Cosmetic pigments typically exist in a dry powder form, and the process of dispersing these pigments plays a vital role in enhancing their opacity or transparency, increasing gloss, and unlocking their full color potential. To achieve optimal color development, it is essential to thoroughly disperse and stabilize the pigments within a suitable vehicle while maintaining their primary particle size.

This dispersion process requires intense high shearing and milling techniques to ensure complete powder-to-liquid integration. Controlling particle size is also a critical factor in maximizing color development in cosmetics because smaller particles provide improved light absorption due to the resulting increased surface area. By utilizing best-in-class milling equipment, you can generate consistent and superior products and enhance the overall quality of them, whether you’re creating soap and shampoo or mascara.

Need Help? Contact Us Today!

-

Headquarters

-

Parts & Service

Industry Benefits

Creams & Lotions

Creating consistently luxurious and effective creams and lotions requires top-notch milling equipment for powerful particle size reduction, resulting in a more consistent end product and streamlining the efficiency of the manufacturing process. An improved milling process also ensures successful pigment distribution, leading to better color development and overall product quality.

Sunscreen - TiO2 & Zinc Oxide

Innovative milling equipment makes all the difference for TiO2 and Zinc Oxide sunscreen production, ensuring uniform and reliable products that meet the necessary metrics for UV protection while also delivering superior sunscreen performance and improved customer satisfaction.

Soap & Shampoo Concentrates

Particle size reduction is essential for high-quality soaps and shampoos. It not only ensures a dependable end product but also reduces the required production time and enables a uniform pigment distribution to improve the products’ color and visual appeal. Vacuum-capable units are also available for water-based applications and can effectively remove trapped air to eliminate foaming issues.

Nail Polish

Efficient milling equipment for nail polish production enables the effective breakdown of tough-to-grind pigments, allowing manufacturers to maximize gloss and transparency and ensure better color consistency for vibrant, uniform shades across their product line.

Liquid Eyeliner

Updating the liquid eyeliner production process with new milling equipment ensures a better end product to meet customer demands with maximized color development, extended yields of expensive pigments, and enhanced opacity and texture. With the superior efficiency of Hockmeyer machines, you’ll produce consistent, high-quality eyeliners that exceed expectations.

Liquid Lipstick

Liquid lipstick production benefits greatly from the control level that high-quality milling equipment offers, enabling precise management of texture, color, and gloss to ensure consistently beautiful results. By employing the best milling technology, manufacturers can guarantee liquid lipsticks that meet their customers’ specifications.

Mascara

Investing in high-quality milling equipment for mascara production offers numerous benefits. It allows you to maximize color development, improve the color of your mascara, and lengthen the life of expensive pigments. Hockmeyer machines provide superior efficiency compared to other brands, allowing you to streamline this manufacturing process and increase productivity.

Featured Industry Solutions

-

HCP Immersion Mill

Machine Features Multiple tank positions with 360º rotation available Minimal cross-contamination, easy clean-up, and low solvent loss Maximizes color development, strength, gloss, durability, and yield Reduction of process time versus…

View HCP Immersion Mill

-

HCPS Immersion Mill with Sweep Blade

Machine Features Interchangeable single-arm sweep and helical sweep design Keeps the side wall clear and improves heat transfer Ideal for high viscosity products Patented auger feeds high viscosity materials through…

View HCPS Immersion Mill with Sweep Blade

-

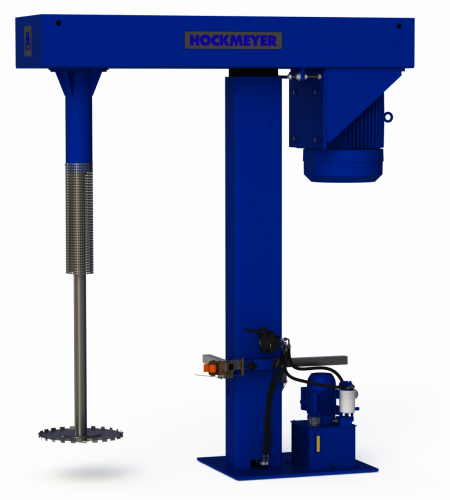

HHL-II Dual Shaft Mixer/Disperser

Features/Options Available Sizes from laboratory units to 3500 gallons Hoist or tank mounted configuration Inverter driven motors Stainless steel or carbon steel material of construction Helical or anchor sweep low-speed…

View HHL-II Dual Shaft Mixer/Disperser

-

HHL-III Triple Shaft Mixer/Disperser

Features/Options Available Sizes from laboratory units to 3500 gallons Hoist or tank mounted configuration Inverter driven motors Stainless steel or carbon steel material of construction Helical and anchor sweep low-speed…

View HHL-III Triple Shaft Mixer/Disperser

-

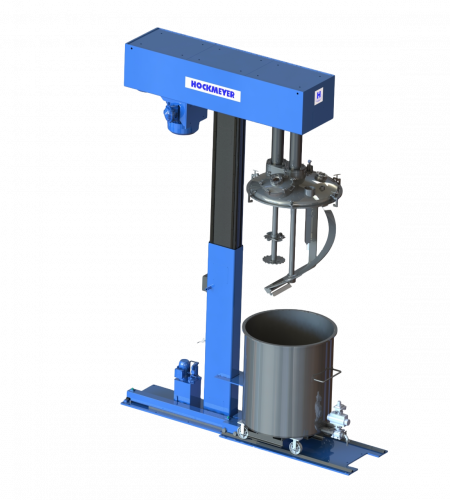

HVI Hoist Mounted Disperser

Variable speed, single-shaft mixer to disperser, dissolve, deagglomerate & emulsify solid particles in a liquid.

View HVI Hoist Mounted Disperser

-

HVIE Hoist Mounted Disperser Air/Oil Lift

Machine Features Available in explosion-proof (XP) and non-explosion-proof (TEFC) packages Standard controls Air-over-oil lift Standard post mixer What is a Disperser? A Disperser is a single-shaft mixer used to break…

View HVIE Hoist Mounted Disperser Air/Oil Lift

-

NEXGEN™ Vacuum Recirculation Mill

Machine Features Remove the air in the slurry – no more foaming issues In-the-mill vacuum Flexibility for batch volumes Hook up to any tank: portable or permanent Sanitary fittings for…

View NEXGEN™ Vacuum Recirculation Mill

-

NEXGEN™ Vacuum Rotor Stator

DISPERSION TECHNOLOGY. FAST. PATENTED The process takes place in a temperature-controlled environment to preserve formulae characteristics and function. A thorough cooling system covering the chamber and return lines quickly mitigates…

View NEXGEN™ Vacuum Rotor Stator

Why Choose Hockmeyer

Hockmeyer Is the Leader in Dispersion and Milling for Color Cosmetics & Personal Care Products

Whether particle size reduction, dispersion, mixing and milling, or other process requirements are the goal, Hockmeyer’s industry-leading equipment and extensive experience make the company a trusted partner for businesses in cosmetics and personal care products seeking high-quality solutions. With a rich history of excellence and a focus on customer satisfaction, Hockmeyer continues to be an industry leader and is committed to continued innovation in the years to come.

Test Your Product Free. Schedule a Test Today!

At Hockmeyer, we're committed to making your product the highest quality possible, whether you need milling, mixing, dispersion or agitation. Schedule your product to be tested in one of our demo machines and see the Hockmeyer difference for yourself.

Services

-

Field Training & Support

Hockmeyer is dedicated to providing best-in-class support to maintain the lifespan and efficiency of your Hockmeyer equipment.

-

Equipment Support Program

Learn about how Hockmeyer can provide dedicated service, maintenance, and training through our Equipment Support Program.

-

Customer Testing-Applications Lab

Don’t trust promises, trust results! Hockmeyer offers it’s Customer Service Laboratory to show you exactly how our equipment will increase your product quality and efficiency!

Cosmetics & Personal Care Frequently Asked Questions

-

How can Hockmeyer’s equipment assist in the cosmetic manufacturing process?

Hockmeyer machines offer an enhanced technology that addresses the limitations of traditional roll mills in cosmetic pigment grinding. These machines reduce operator interface and process time while ensuring safety with multiple safety features and provide the ability to gather data for formula adjustments and future decision-making. The Hockmeyer team is committed to delivering high-quality equipment for mixing, dispersion, milling, and vessel washing as well as continuously improving designs to enhance efficiency.

-

What equipment is ideal for pigment distribution in cosmetics?

The perfect equipment for cosmetic pigment dispersion depends on the specific product you’re creating. For products like liquid eyeliner, nail polish, foundation, sunscreen, and tinted moisturizer, consider the HVI and HCP low-viscosity dispersion and milling, while for high-viscosity dispersion and milling for products like lipstick, concealer, mascara, and crème blush and foundation, consider the HHL and HCPS. For applications where removing trapped air and eliminating foaming are required, the HNG is an excellent fit.

-

Does Hockmeyer provide small-batch cosmetic manufacturing equipment?

Yes! Hockmeyer equipment is scalable, so it can be used at any stage in the production process, and there are many opinions available to businesses. Additionally, Hockmeyer’s Customer Service and Testing Facility is equipped with laboratory models of all the company’s most popular equipment, and initial testing is always free!

-

What are the FDA’s cosmetic manufacturing regulations?

The cosmetics and personal care products industry prioritizes consumer safety and adheres to strict Food and Drug Administration (FDA) regulations, and it is considered one of the safest product categories regulated by the FDA. The Modernization of Cosmetics Regulation Act (MoCRA) of 2022 further enhanced product safety and innovation, and cosmetic companies exceed legal requirements by implementing additional safety measures, such as rigorous ingredient selection, evaluations, testing, labeling, quality control, and secure packaging.